Corrosion isn’t always obvious on steel structures. It often lurks beneath the surface, covered by industrial coatings that are designed to prevent corrosion. When critical industrial coatings deteriorate and fail, moisture and chemical elements can access and corrode steel.

Learning to identify breakdowns and weak points in industrial coatings can help identify corrosion that is not visible on the surface.

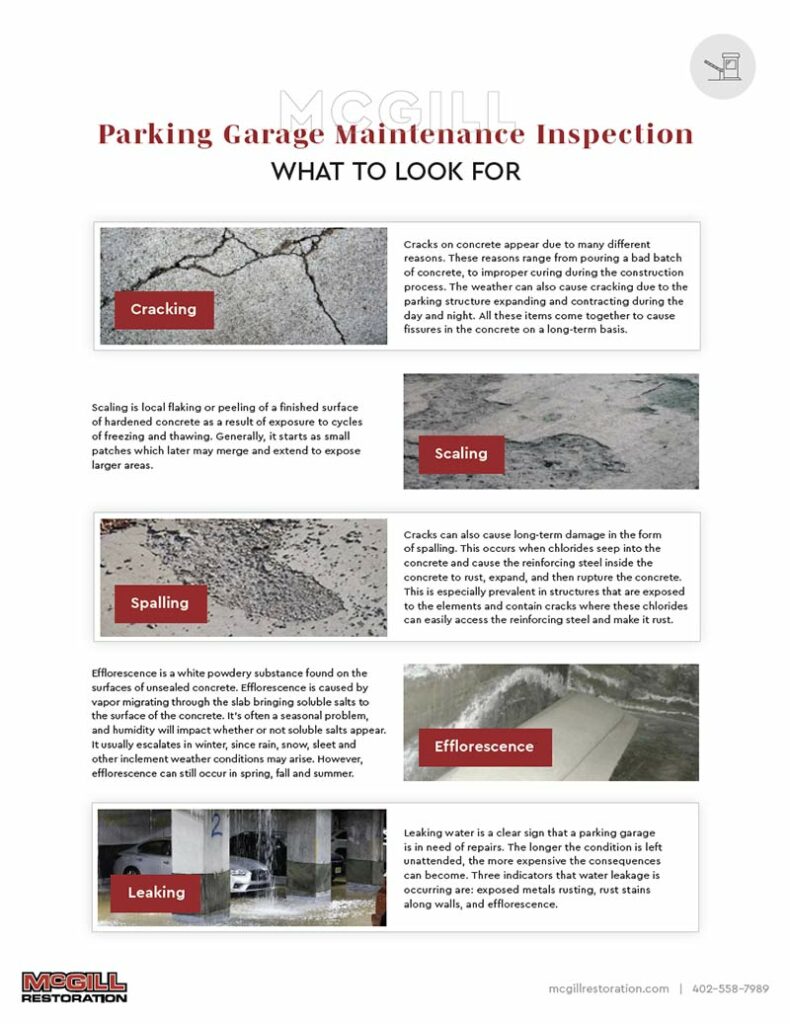

Industrial Coating Signs of Failure

Complete regular inspections to find issues with industrial coatings. The following are common signs that your coatings are due for renewal and replacement.

Chalking

UV light deteriorates many coating types over time and chalking occurs. If the surface releases a powdery substance, the coating is starting to degrade and may result in coating failures. Urethane is UV stable and offers an ideal solution to protect against regular UV exposure.

Cratering

Look for depressions or craters in the coating to identify weak points. Cratering occurs when air is present in the mixture or beneath the coating during application. The air pockets release and the coating craters are possible points of water and chemical element penetration.

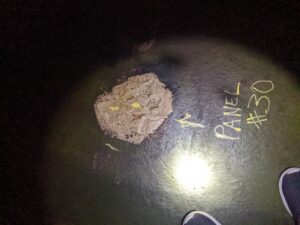

Blistering

The opposite of cratering is blistering. Rather than having concave depressions, the coating will blister outward. This means a foreign element is trapped between the steel and the coating and is projecting outward. The failed adhesion becomes problematic as the blisters eventually crack and create coating failures.

Cracking

An obvious sign of industrial coating failure occurs in the form of cracking. The cracks can form from stress when steel experiences rapid temperature changes that cause expansion. Movement and material flexing can also stress the steel and cause cracking. When coatings are cracked, it means a more flexible industrial coating should be used.

Checking

This looks like a sand flat that is completely dried out. Checking is a clear visible sign of coating failure with cracks and scaling. Checking frequently happens when a new coating is applied over an old coating that is not compatible. It can also occur from poor industrial coating selection.

This looks like a sand flat that is completely dried out. Checking is a clear visible sign of coating failure with cracks and scaling. Checking frequently happens when a new coating is applied over an old coating that is not compatible. It can also occur from poor industrial coating selection.

Flaking and Peeling

When a coating experiences adhesion failure, flaking and peeling are noticeable. The same thing can occur on steel tanks or an interior wall in a house. Adhesion failure is the result of application over a dirty or contaminated surface, glossy surface, or an existing coating where adhesion is not possible. Surface preparation is critical for any new industrial coating application.

Can You Add Protective Coatings Over Old Materials?

The best solution for any new application of industrial coatings is a fresh surface. This requires removing old coatings and prepping the steel for a new, multilayer application. In many instances, a base layer followed by epoxy and a urethane top coat will provide ample protection against the elements and chemical exposure.

The entire removal and replacement of industrial coatings are expensive; however, it’s not the only solution. Adding new coatings over old materials is acceptable if the materials are compatible. You can determine this by referencing spec sheets or testing the base materials to identify the chemical composition.

It is imperative that you confirm the materials and compatibility because using a mismatch will result in a failed protective coating. That ultimately means the materials and labor used are a wasted expense.

Are your industrial coatings losing resiliency?

Don’t let corrosion take over your steel structures when corrosion prevention methods from the experts at McGill Restoration can restore value to your investment. Get in touch to schedule an inspection today.