What’s the difference? Learn how joint sealants and expansion joints can protect your commercial structure.

Joints, gaps and cracks are among the most vulnerable places on commercial structures. During construction, slabs are poured, columns are formed and each piece of the building is fit together to make a uniform structure. Where these elements meet, gaps are formed and they must be sealed.

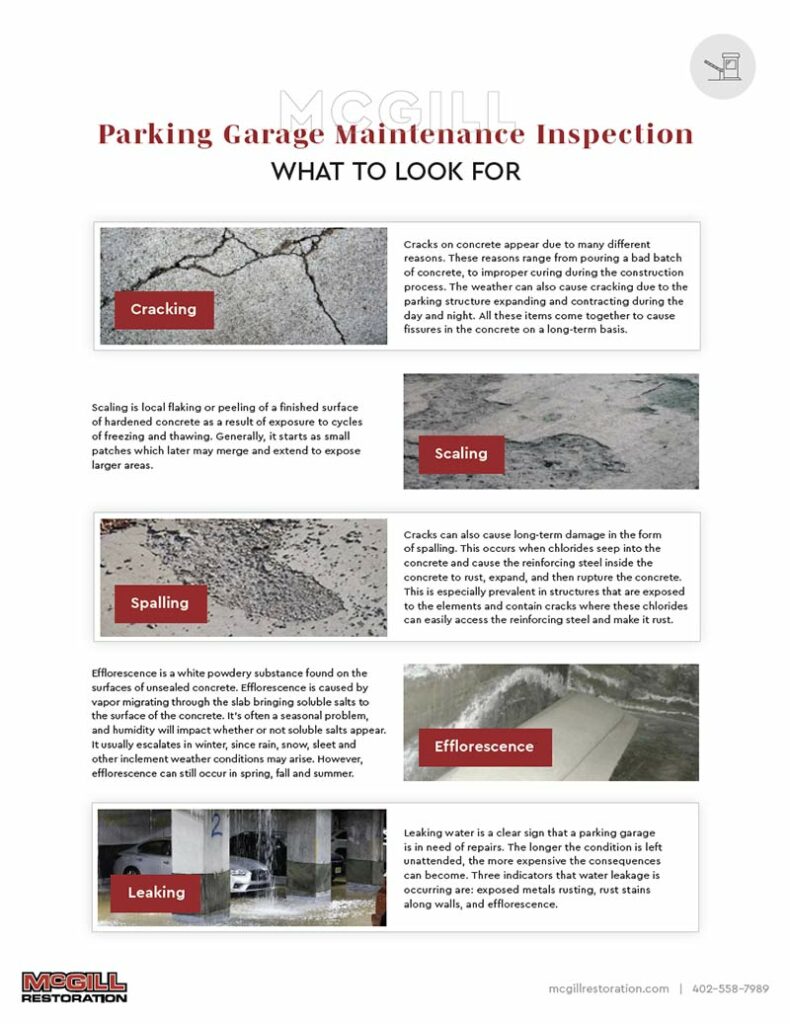

Without joint sealants and expansion joints, the gaps are susceptible to water entry which can result in damage to the structure. Crumbling and degrading concrete, rusted rebar, corroding steel supports and general decay can creep into the heart of the building. With proper sealing and maintenance, however, the joints will reject water and your commercial structure can live a long and healthy life.

Understanding Joint Failures

Before we discuss the types of joint sealants, it’s important to understand the consequences of failures. Sealing joints creates a primary defense against water entry. Water is the leading cause of premature material failures on commercial structures, as water is also a carrier of destructive chemicals.

Runoff from roadways, salts/chlorides, and a number of common chemicals from vehicles are corrosive and destructive. When these contaminants breach the joints and filter into the structure, the destructive properties of water are amplified and corrosion can quickly accelerate deterioration.

Selecting the proper joint sealant material and using best practices for installation and maintenance (see our maintenance checklist) is imperative to prevent moisture and chemical compounds from eating away at your investment. Take the time to inspect joints for damage, renew and maintain joints regularly and use the proper joint sealants or expansion joints to extend the lifespan of your structure.

Here’s everything you should inspect to identify damage to joint sealants.

Joint Sealants 101

Every crack and crevice less than one-inch wide is a candidate for joint sealants. Two primary types of sealants exist with wide-use applications – urethane and silicone.

Before any joint sealant is selected and applied the prep work is intensive. This is where contractors are really differentiated. Without a clean and properly prepared surface, the sealant will not bond. If sealants don’t bond to the surface they aren’t serving their purpose and will allow the elements into your structure!

Preparation involves removing old joint sealant materials and grinding to create the right surface profile for installation. After the grinding is completed, joints are cleaned to remove debris and particles that may interfere with adhesion. With a clean surface, the joint is ready for sealant installation.

Urethane Joint Sealants

Urethane uses a two-part process that involves mixing prior to application. Thorough mixing at a suitable temperature is important for optimal performance once installed. Urethane is common on horizontal surfaces and for traffic-grade applications.

Urethane is very durable; but the traffic load and exposure to elements is a factor of the lifespan and like any sealant, regular inspections will help determine when joint sealant renewals are necessary.

Silicone Joint Sealants

When differing materials meet, silicone is the ticket. The material is flexible, resilient, and capable of bonding to masonry, metal, and other common construction materials. Think about places where window frames and metal edging have gaps between the masonry.

High-grade silicone performs under wide temperature swings and it’s a highly effective joint sealant. Grinding and cleaning the joint is critical however because silicone will not adhere well without thorough prep work.

Expansion Joints Fill the Big Gaps

While joint sealants cover the small gaps (1/16” to 1”), expansion joints are there for everything else. They come in a variety of styles and sizes but the core material is neoprene. Expansion joints can be used in vertical and horizontal applications. Rail bridges, parking garage decks and a number of other masonry and steel structures utilize expansion joints regularly.

The lifespan on these joints varies based on style, usage, and if in horizontal applications – traffic (pedestrian or vehicular). Snowplows and other machinery can puncture and damage joints when used without caution but they withstand regular road traffic well.

Selecting the right style and fit is important. With the best-fit expansion joint and a proper installation, your big gaps will be fortified and ready to fend off water, chemical elements and anything trying to enter and damage the structure.

Are joints in need of repair? Get in touch with the pros at McGill Restoration to inspect and plan to protect the most vulnerable aspects of your commercial structure.