Spring seasonal parking structure maintenance helps to address and repair post-winter issues before they cause long-term damage.

Without seasonal maintenance, failed joints, damaged coatings, and other common problems will prevail and allow for faster deterioration of the structure.

Why is Spring Critical for Parking Garage Maintenance?

Winter is hard on parking structures and that makes spring the best time to perform annual maintenance. Snow removal and plowing often cause damage to joints and coatings, creating a need for immediate maintenance when the freeze-thaw cycles end.

Performing maintenance multiple times throughout the year is good but spring is a top priority for preventative maintenance that protects the structure throughout the summer, fall, and subsequent winter.

Follow this Simple Parking Garage Maintenance Process

Luckily, preventative spring maintenance isn’t complicated and in most years, is not exceptionally time-intensive. A simple wash and review of the structure will suffice. If any damage is noted, implementing immediate repairs will save on long-term costs associated with damage from failed joints, failed coatings, and masonry damage.

You can also use our free Parking Garage Maintenance Checklist to help guide you through the process. Or if you are unsure give us a call and we can help guide you.

Step #1 – Power Wash Your Structure

Winter delivers salt and chemicals that are corrosive and harmful to all building materials if left unchecked. Power washing removes these harmful elements, leaving your structure clean and ready to continue operating normally. A clean garage also offers more aesthetic appeal and makes customers feel safer.

You can use a simple pressure washer to clean the surfaces or add detergent to really clean out the crevices. Ideally, you can pressure wash with warm water and detergent but any washing is adequate.

Conduct the pressure wash after the spring melt when you no longer expect road salting and plowing to occur.

Step #2 – Conduct a Visual Review

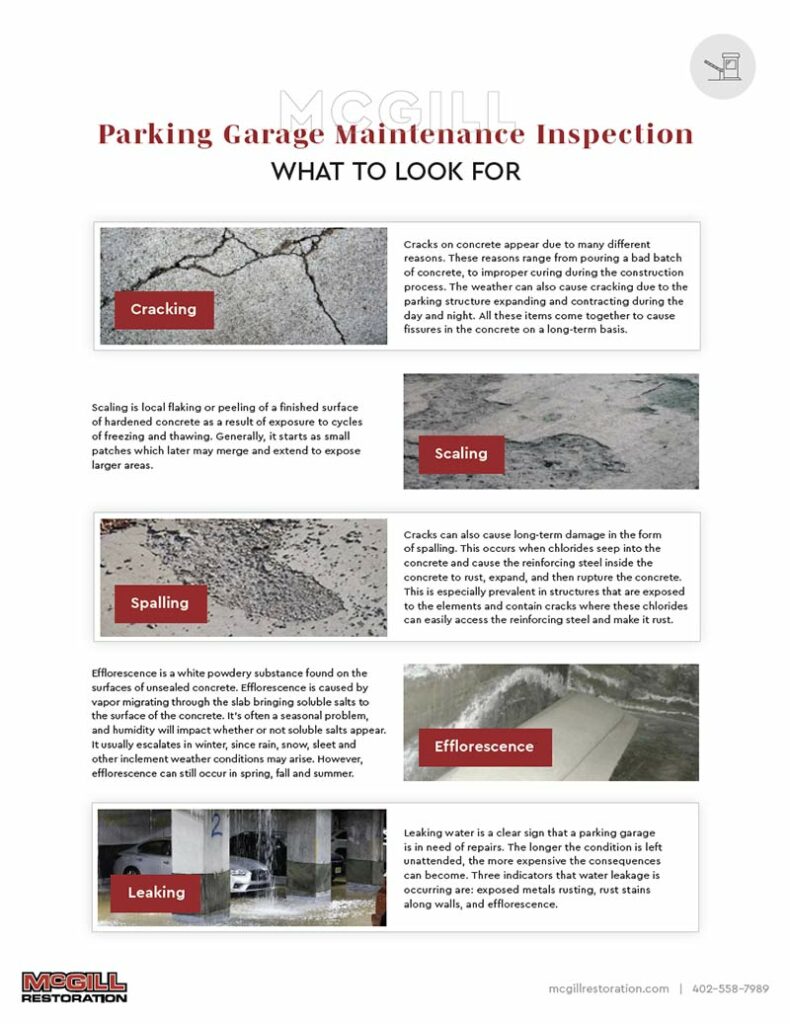

The visual review is not difficult, but it does help to know what you are looking for in terms of damage and critical elements. Training property managers by conducting a review alongside a professional restoration company will prepare them for future maintenance. The following are important factors to review in your spring preventative maintenance process.

Joint Sealants – Gaps create opportunities for water entry that ultimately erodes the structure and creates serious damage. Joint sealants prevent this from happening but they do endure plenty of wear and tear during winter. Inspect your joints and identify areas where these sealants require renewal. When they pull away from the joint sides, show alligatoring, or lose cohesion, it’s time for renewal.

Traffic Coatings – Metal plow blades can easily damage traffic coatings. Any damage (large or small) to the traffic coating will cause premature failure. The damage is visible and should be addressed by patching or removing and replacing the coating. The extent of the damage will determine the level of repairs required.

Expansion Joints – These neoprene joints are critical and are often pierced by plow blades during the winter. Do a thorough review of expansion joints because early detection of damage can be repaired with patches in many cases. Waiting for too long allows the pierced sections to deteriorate requiring expensive replacements.

Concrete Condition – The general condition of concrete is also important. Look for cracking and deterioration throughout the entire inspection. These issues are often the result of failed joint sealants, pervasive exposure to water, and the freeze-thaw cycle.

Step #3 – Engage a Professional

After conducting the review, it’s time to consider engaging a professional. Pressure washing and even basic maintenance may fall within the scope of your maintenance team. For specialized work like expansion joint repairs and replacements, traffic coatings, and concrete restoration, contact the professionals at McGill Restoration.

Our team also works with stakeholders and property managers to develop cost-effective preventative maintenance plans. Empowered with a plan and the know-how, property managers can execute spring maintenance with confidence.

Understanding the Value of Maintenance

Why bother with spring maintenance? The reality parking structure owners face is one of economics. Without spring maintenance, small problems like a pierced expansion joint can turn into more costly issues.

That expansion joint can be patched for a few hundred dollars when the damage is identified early or you can wait for failure and spend upward of ten thousand dollars for a replacement. This same story applies to nearly every important coating and joint sealant in the structure.

Identifying issues in the spring also makes it possible to hold snow removal companies accountable for damage. Utilizing contracts that specify the need for non-metal blades and having accountability built into the contract means your maintenance costs are mitigated when another party is responsible for the damage.

Lastly, maintenance means you can keep the garage open without shutdowns for major restoration work. We have worked on parking structures for busy medical facilities like the Bryan Medical Center and an important bank in Helena, MT where avoiding closures is a high priority.

With regular maintenance, you can limit closures and inconveniences to users who depend on your parking.

At McGill Restoration, we help parking structure owners realize the maximum value of their investments. Use our Parking Garage Maintenance Checklist to guide your spring review or get in touch with our team to create a custom spring preventative maintenance plan.